10 Best Locking Grease Coupler 2026 in the United States

Our technology thoroughly searches through the online shopping world, reviewing hundreds of sites. We then process and analyze this information, updating in real-time to bring you the latest top-rated products. This way, you always get the best and most current options available.

Our Top Picks

Winner

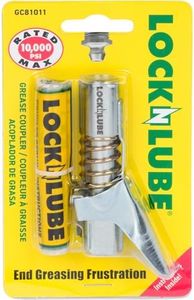

LockNLube Grease Gun Coupler locks onto Zerk fittings. Grease goes in, not on the machine. World's best-selling original locking grease coupler. Rated 10,000 PSI. Long-lasting rebuildable tool.

Most important from

31831 reviews

The LockNLube Grease Gun Coupler is designed for those who frequently maintain machinery, thanks to its innovative locking mechanism that securely attaches to Zerk fittings. One of its standout features is the ability to lock on tightly, allowing users to operate the grease gun with both hands, which can make the task quicker and cleaner. With a pressure rating of up to 10,000 PSI, it can handle high-pressure applications, making it suitable for both professional and DIY use.

Compatibility is a strong point, as it works with all grease guns—whether they are manual, battery-powered, or pneumatic—and fits both SAE and metric Zerk fittings with the help of included adapters. This versatility means that it can be a valuable addition to anyone's toolbox, from casual users to experienced technicians. The fact that it is rebuildable, with a spare kit included, adds long-term value, allowing users to maintain performance over time.

While the LockNLube is user-friendly and generally effective, some users may find that it requires a little practice to master the thumb lever operation. Initially, it might feel bulky for those accustomed to traditional couplers. Additionally, while the locking mechanism is a significant advantage, there can be occasional issues with debris interfering with the locking jaws if not properly maintained, which could lead to leaks.

Most important from

31831 reviews

THINKWORK Grease Gun Coupler Set, Strong Lock on Greases Gun Couplers with 90° Grease Coupler Adaptor,12000 PSI Quick Release Grease Coupler Compatible with All Grease Guns 1/8" NPT Grease Gun Fitting

Most important from

537 reviews

The THINKWORK Grease Gun Coupler Set offers some impressive features, especially for those working in tight spaces. Its small size, with a diameter of 0.53 inches, makes it particularly suitable for confined areas, which can often be a challenge for standard-sized couplers. This is a great advantage for automotive repairs or working on large machinery where space can be limited.

One of the standout qualities of this coupler set is its high-pressure rating of 12000 PSI. This indicates that it's capable of handling demanding applications without risk of failure, which is crucial for efficiency and safety in both commercial and home garage settings. Additionally, the upgraded 6-jaw locking mechanism with aviation-grade sealing gaskets promises reliable performance and minimizes the chances of leaks, which could otherwise lead to wasted grease and mess.

The set's compatibility is another plus point; it fits all 1/8” NPT grease guns, making it versatile for various models, including mini, pneumatic, and electric grease guns. This broad compatibility allows for flexibility and ease of integration into existing setups without the need for additional adapters. In terms of usability, the single-lever design facilitates easy one-handed operation, which can significantly enhance the user experience by allowing for quick locking and releasing. This is particularly beneficial for those who require efficiency and speed in their tasks.

Most important from

537 reviews

LockNLube Grease Gun Coupler XL - Extra reach for recessed grease fittings

Most important from

4832 reviews

The LockNLube Grease Gun Coupler XL is designed to enhance the user experience for anyone needing to grease hard-to-reach fittings effectively. With a high pressure rating of 10,000 PSI, it can handle tough jobs without risk of leaking. One of its standout features is the locking mechanism that secures it to the fitting, eliminating worries about it popping off during use. This hands-free operation is particularly helpful when working under pressure, allowing for a more efficient greasing process.

The coupler's compatibility is impressive; it fits all standard grease guns and both SAE and Metric Zerk fittings. This means you can easily swap it with your existing coupler without needing any additional equipment. Its extra reach of over 3.5 inches makes it ideal for accessing recessed fittings like those found on PTO shafts, axles, and U Joints, which are often tricky to grease.

On the plus side, the included rebuild kit is a significant advantage, allowing users to replace seals and jaws without the need to buy a new coupler. This feature not only saves money but also extends the lifespan of the tool. The LockNLube Grease Gun Coupler XL is a strong choice for those who frequently work with difficult-to-access grease fittings, blending convenience and performance effectively for both casual users and professionals alike.